Progressive cavity pumps (PCPs) are known for their versatility and ability to handle a wide range of fluids. However, like any mechanical equipment, they can experience failures. Here’s a breakdown of common PCP failures, their causes, and potential solutions.

Common Progressive Cavity Pump Failures

Sealing Failures:

- Causes: Wear and tear, misalignment, contamination, or improper installation.

- Solutions: Regular inspection and maintenance, proper lubrication, and using high-quality seals.

Rotor and Stator Wear:

- Causes: Abrasive fluids, excessive pressure, or misalignment.

- Solutions: Using appropriate materials for the fluid being pumped, maintaining proper alignment, and regular inspections.

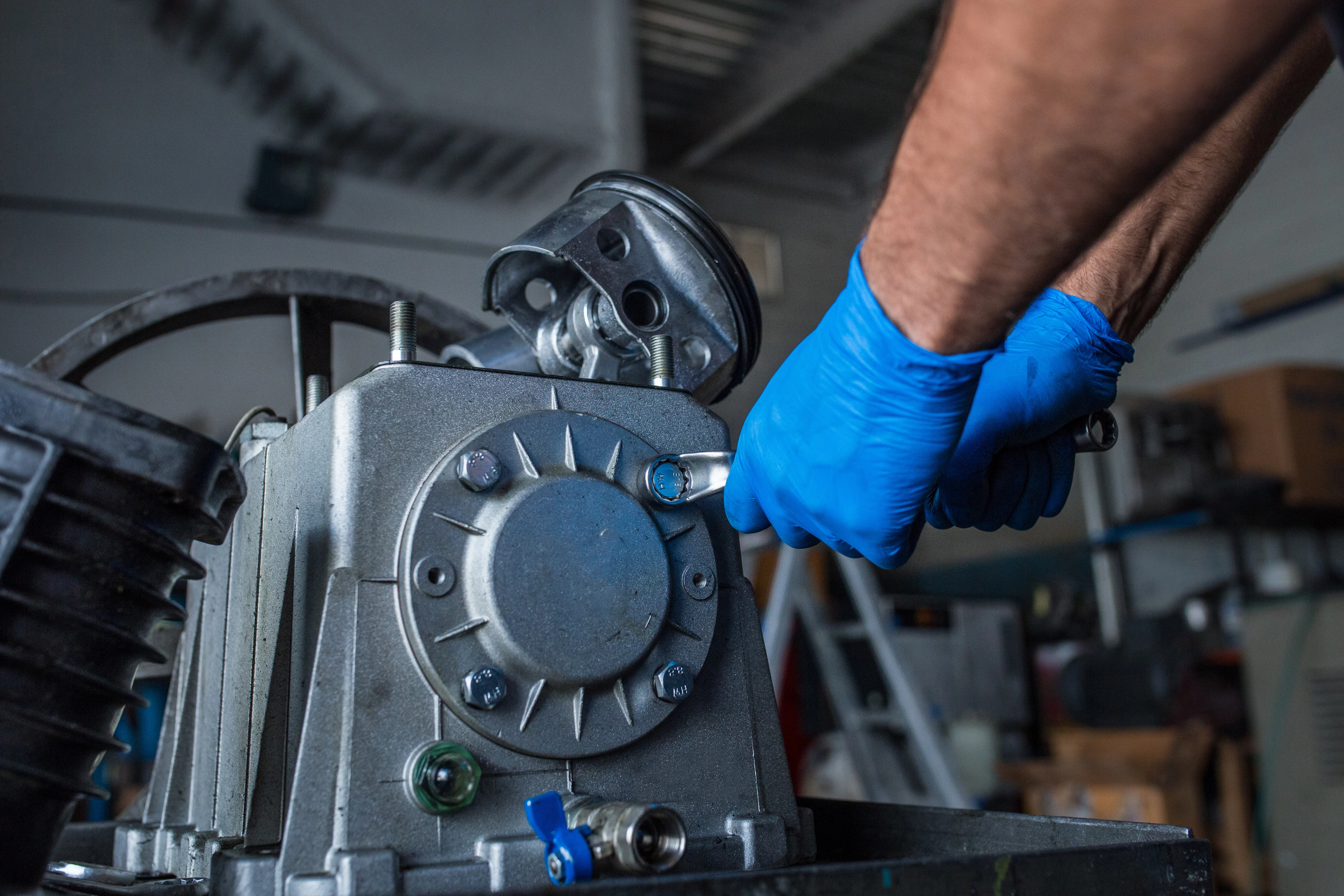

Bearing Failures:

- Causes: Overloading, contamination, or improper lubrication.

- Solutions: Proper lubrication, avoiding overloading, and regular inspections.

Cavitation:

- Causes: Insufficient net positive suction head (NPSH) or excessive flow rates.

- Solutions: Ensuring adequate NPSH, adjusting flow rates, use a booster pump or suction pipe size at least similar or larger than pump suction size.

Motor Failures:

- Causes: Overloading, overheating, or electrical faults.

- Solutions: Proper sizing of the motor, avoiding overloading, and regular maintenance.

Fluid Handling Issues:

- Causes: Thick or viscous fluids, solids in the fluid, or gas pockets.

- Solutions: Pre-filtering the fluid, using appropriate pump models for viscous fluids, and ensuring proper venting.

Prevention and Maintenance Tips

To minimize PCP failures, it’s essential to follow these preventive maintenance practices:

- Regular Inspections: Conduct routine inspections to identify potential issues early on.

- Proper Lubrication: Use the recommended lubricants and follow lubrication schedules.

- Fluid Compatibility: Ensure the pump is compatible with the fluid being pumped.

- Correct Installation: Follow the manufacturer’s guidelines for installation.

- Avoid Overloading: Operate the pump within its rated capacity.

- Regular Cleaning: Clean the pump and associated components as needed.

By understanding common PCP failures and implementing effective maintenance strategies, you can significantly improve the reliability and lifespan of your pump.

If you’re looking for reliable progressive cavity pump manufacturers or suppliers, consider Thermac Engineering