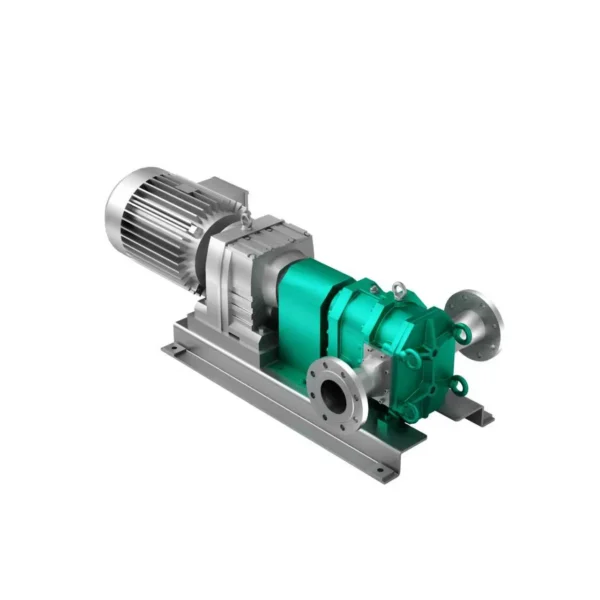

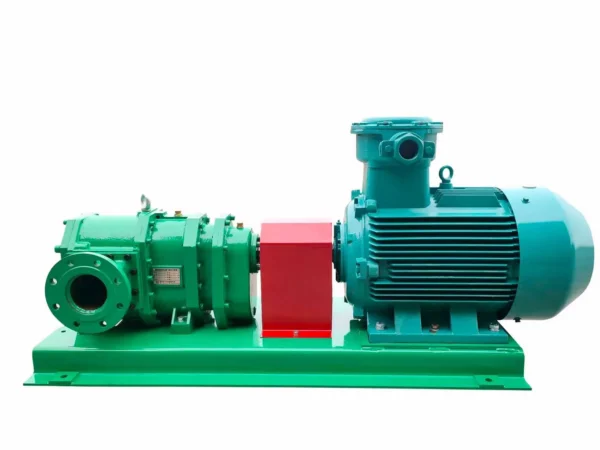

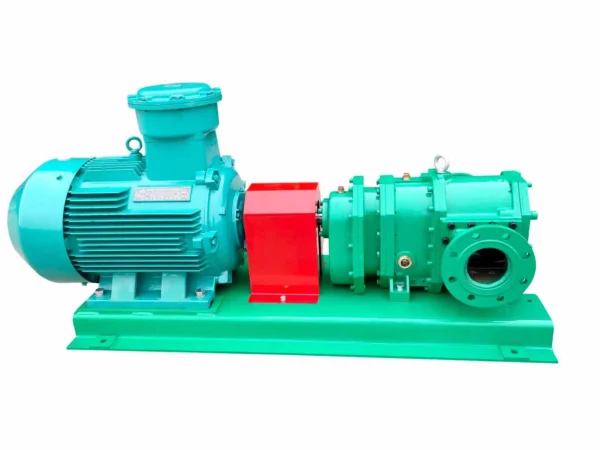

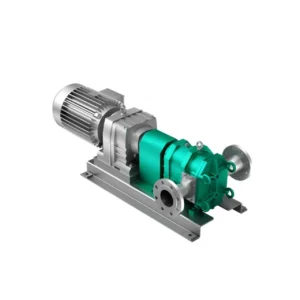

Easy maintenance

The structural design of the Flomac rotary lobe pump is very simple, and all models of the pump retain a simpledesign style. The quick-release pump cover provides convenience for the maintenance of the pump withoutdismantling the pipeline.

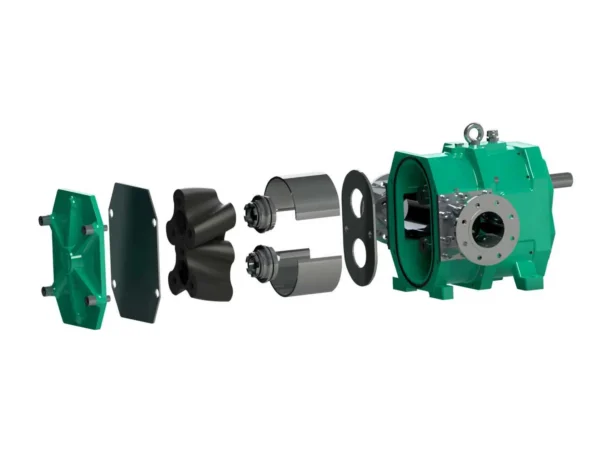

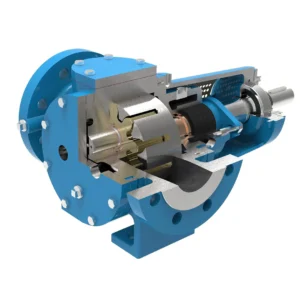

Working principle

Flomac rotary lobe pumps are self-priming, valveless, positive displacement pumps. Two synchronously reversed

rotors mesh with each other and form a small cavity with the pump cavity. The medium filled in the cavity is constantly

pushed from the inlet end to the outlet end by the rotating rotor. The design structure of the lobe pump is completely

symmetrical. By changing the rotation direction of the pump, the flow direction of the pump can be changed, and

reversible operation can be easily realized.Lobe pump (rotor pump) meets API676 or SH/T 3151 standard.

Suitable medium for conveying

Flomac rotary lobe pumps are self-priming, valveless, positive displacement pumps. Two synchronously reversed

rotors mesh with each other and form a small cavity with the pump cavity. The medium filled in the cavity is constantly

pushed from the inlet end to the outlet end by the rotating rotor. The design structure of the lobe pump is completely

symmetrical. By changing the rotation direction of the pump, the flow direction of the pump can be changed, and

reversible operation can be easily realized.Lobe pump (rotor pump) meets API676 or SH/T 3151 standard.

- Strong self-priming: the maximum suction distance

can reach 8.5-9.5 meters - Excellent wear resistance

- Online maintenance

- Can be dry running

- Energy saving and power saving, high efficiency

- Reversible flow direction

- Mixed transport of multi-phase media: mixed transport

of gas, liquid and solid - No clogging

- Ultra-wide medium viscosity delivery range and gentle pumping with low shear effect.

- Compact structure, small footprint

4 Series with 16 models constitute the perfect product line of Flomac rotary lobe pumps. The maximum flow rate is up to 3200m³/h, the maximum pressure is up to 2.5MPa and the flow rate of 5000m³/h is under development. The modular design of the pump makes the same commonality of the same series and increases the universal interchangeability of parts.